Showroom

Cabinet dryers provide flexibility in drying capacity and

customizing possibilities. They come in a range of sizes to accommodate diverse

drying requirements, from tiny units appropriate for small homes or spaces to

big units for commercial or industrial use.

Chainsaw and bicycle owners may perform a quick and simple maintenance

activity by applying chain oil. You can

maintain the chain's smooth operation, lessen friction-related wear, and shield

it from environmental harm by frequently adding oil to it.

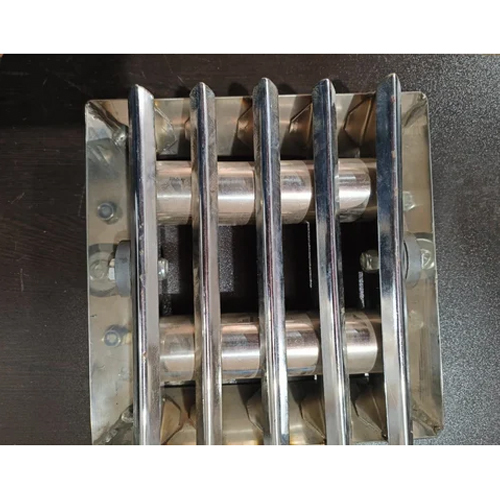

Using a hopper magnet has

advantages beyond just preventing contamination. These magnets assist increase

overall operating efficiency and save downtime by eliminating ferrous

impurities. They prevent potential harm from metal shards to downstream

machineries such as crushers, grinders, mixers, or extruders.

Plastic materials in both rigid and flexible forms can be processed

using plastic granulator machines.

They have the capacity to treat a variety of plastic waste materials, including

bottles, containers, films, pipes, and more. To meet certain material kinds and

processing needs, the machines can be modified.

The uses for robotic arms

are numerous and varied. They are extensively employed in the fabrication of

goods in the pharmaceutical, food processing, electronics, and automotive

sectors. By automating repetitive processes, decreasing mistakes, and boosting

throughput, they may considerably improve production efficiency in the

manufacturing industry.

An key piece of machinery for efficient and effective mixing,

blending, and storing of liquids, powders, or granular materials is the storage mixer. This adaptable equipment

is essential for assuring constant product quality, raising productivity, and

optimizing production procedures.

For producers, vertical plastic

mixers provide a number of benefits. They enable customisation depending on

particular material needs by offering fine control over mixing factors

including speed, duration, and intensity. Better material flow and mixing

effectiveness are encouraged by the mixer's vertical position.

In order to automate the process of loading plastic granules or resin

ingredients into processing machines, Granule

Auto Loaders are crucial pieces of machinery utilized in many industrial

businesses. This effective and dependable tool simplifies the manufacturing

process and ensures an accurate and constant supply of raw materials.

The plastic recycling business relies heavily on low speed granulators to effectively convert plastic waste into

smaller, more uniform-sized grains. This adaptable granulating apparatus

provides a dependable and efficient method for breaking down large plastic

materials into controllable particles that may be processed further.

A metal separator is a

crucial piece of machinery used in several sectors to find and get rid of

metallic impurities in bulk materials. This adaptable and dependable machine

provides a practical option for guaranteeing product purity, avoiding equipment

damage, and preserving the caliber of the finished product.

To safely bind molds to injection molding machines, a mold clamp is a crucial instrument used

in the plastic injection molding industry. This adaptable clamp's strength and

dependability provide the stability and accuracy necessary for effective mold

operation.

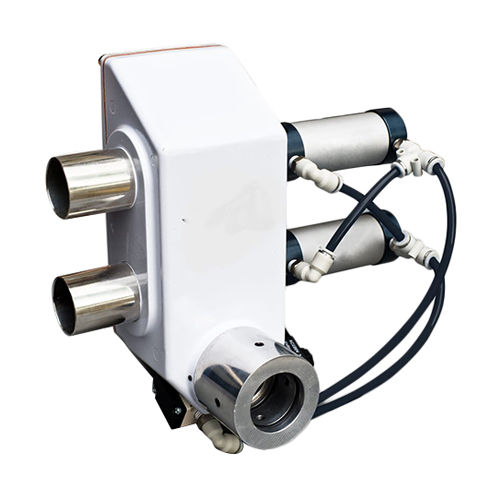

A clever and adaptable tool, a proportional

valve is frequently employed in several industrial applications to

accurately control fluid flow, pressure, or direction. This cutting-edge valve

provides outstanding precision and reactivity, making it a crucial part of

systems that need for exact control over fluid properties.

Send Inquiry

Send Inquiry Send SMS

Send SMS